How Do Electrostatic Filters Filter Smoke?

Electrostatic filters are an effective pollution removal technology widely used in ventilation and air purification systems today. Such filters are generally used in industrial facilities, kitchens, vehicles and indoor spaces to capture particles, smoke and other pollutants in the air. However, the question “How do electrostatic filters filter smoke?” is a question asked by many people about the effectiveness and functionality of these filters.

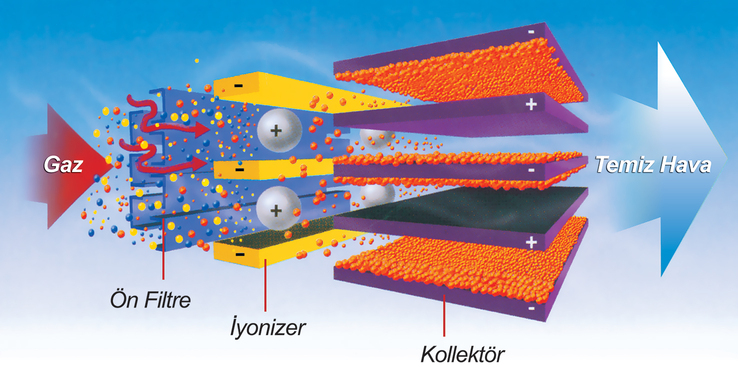

Electrostatic filters use electrical charges to filter pollutants in the air. Basically, these filters create an electric field and charge the particles in the air positively or negatively. The charged particles are then attracted to an electrode of the appropriate polarity and filtered. This system is particularly effective in capturing airborne substances such as dust, smoke, oil vapors and other fine particles. The working principle of electrostatic filters is based on the electrical charging of pollutants in the air and the attraction of these charged substances by the electrodes. Therefore, these filters can capture both fine dust and gaseous particles.

Smoke is a mixture of fine particles and gases in the air. Especially barbecue smoke, cigarette smoke, industrial waste gases and similar smokes contain both gas components and solid particles. Electrostatic filters are quite effective in filtering such smoke. Because solid components of smoke such as particles or oil droplets can be easily captured with electrostatic charge.

Smoke generated as a result of barbecue, cooking or industrial processes usually consists of oil droplets and fine dust. Electrostatic filters can capture such particles with high efficiency. Charged oil particles stick to the filter surfaces thanks to the electrostatic field, which is effective in cleaning the smoke.

However, gas components of smoke such as carbon dioxide, carbon monoxide, nitrogen oxides cannot be cleaned directly with electrostatic filters. Electrostatic filters can only capture particles and a different technology is required for cleaning the gases. However, when the particle content of the smoke is reduced, the density of the gas components also decreases indirectly, which creates an effect that improves the overall air quality.

The effectiveness of electrostatic filters depends on a number of factors. These factors include filter design, air flow rate, materials used, and load capacity. An effective electrostatic filter can trap particles with very high efficiency. However, the efficiency of filters can also decrease over time. Filters need to be cleaned, maintained, and maintained regularly.

Electrostatic filters generally operate at 90% efficiency or higher. High-efficiency models are particularly good at capturing fine dust and oil vapors. However, the size and density of the particles can affect how well the filters trap these particles.

The effectiveness of electrostatic filters requires regular maintenance. Filter elements become dirty as they interact with airborne contaminants, which can cause their efficiency to decrease. In addition, contaminants that accumulate on filter surfaces can interfere with electrical charge conductivity. Therefore, regular cleaning and maintenance of filters is important for long-term effectiveness.

The advantages and limitations of electrostatic filters in filtering smoke and other airborne particles can be:

Advantages of Electrostatic Filters:

High Efficiency: Electrostatic filters can capture fine particles with very high efficiency. This is a great advantage especially for oil droplets and dust in smoke.

Environmentally Friendly: These filters, which work with electrical charges, perform the cleaning process without using chemicals. This offers an environmentally friendly solution.

Long-Term Use: Electrostatic filters can have a longer life than physical filters because the filter elements in most models can be washed and reused.

Low Energy Consumption: These filters can operate with high efficiency while keeping energy consumption to a minimum.

Limitations of Electrostatic Filters:

Inability to Filter Gases: Electrostatic filters cannot clean the gas components of smoke. Therefore, different technologies are needed to clean the chemical components of smoke.

Regular Maintenance Requirement: Electrostatic filters require regular maintenance and cleaning to maintain their effectiveness. Otherwise, their efficiency decreases.

Loading Problems: The filtering capacity varies depending on the amount and size of the particles loaded. Excessively contaminated air can negatively affect the efficiency of the filters.

Electrostatic filters are particularly effective in filtering smoke, particulate dust, oil droplets and fine particles filters. However, gas components remain outside the capabilities of electrostatic filters. It offers an effective solution when filtering smoke, especially barbecue, cigarette, kitchen and industrial smoke. However, the effectiveness of the filters can be further increased with regular maintenance, cleaning and appropriate system design. Electrostatic filters offer a highly effective solution in filtering the particulate components of smoke, but additional technologies are needed for the removal of gases.

İlker KURAN

Alperen Mühendislik Co. Şti.