Operating Room Ceiling Ventilation Units

What is Laminar Air Flow Unit?

Closed and sterile areas where the number of particles, the number of microorganisms, temperature, humidity, fresh air amount, ambient air pressure, air movements and similar parameters are kept under control are called clean rooms. Operating rooms, intensive care units, sterilization rooms, assisted reproductive techniques units, genetic laboratories are places that are in the clean room class.

Ventilation equipment that provides the desired hygienic air quality in clean rooms and directs the air vertically is called laminar air flow units.

Where is Laminar Air Flow Unit Used?

Laminar air flow units are especially used in sensitive applications such as operating theaters, pharmaceutical industry, chemical industry, food production, electronics industry and research laboratories, in vitro fertilization units. Laminar flow units should be used with a ventilation system that complies with the criteria specified in the standards. Laminar flow blowing systems meet the requirements in accordance with the conditions specified in the standards with the hygienic ventilation technique in the distribution and filtering of the air.

The fact that the air quality of the environment is not within the hygiene limits during the operation increases the risk of the patient getting infection during the operation. Laminar flow units are produced to eliminate this problem. These units create a laminar flow on the patients and doctors in the operated area, ensuring protection from bacteria, viruses and microbes.

In laminar flow clean rooms, the air flow moves in a vertical line. At each point of these streamlines that are parallel to each other, the velocity of the air is constant in the range of 0.20-0.45 m/sec.

In turbulent air flow in environments where laminar flow units are not used, the air velocity is in the form of irregular lines in the range of 0.35 m/sec – 0.85 m/sec.

Working Principle of Laminar Air Flow Units

Laminar air flow units are mounted on the operating table. The air coming from the hygienic air handling unit passes through the laminar air flow unit. The particles pushed downwards by the sterile and vertical airflow obtained are drawn out from the exhaust vents. With the positive air pressure created in the operating room, the leakage of polluted air from the outside into the clean air area is prevented.

What are the Features of Laminar Air Flow Unit?

Laminar air flow units are terminal elements that provide ideal ventilation for laminar flow ceilings, operating rooms and similar environments. They provide a terminal velocity and laminar flow between 0.20 m/s and 0.45 m/s in the projection of their size. Thanks to the most important characteristics of laminar flow and hepa filters used, they provide extremely low particle count at the end of the operation. They also minimize the anesthetic gas rate with the positive ventilation they create.

Our laminar air flow units are produced in accordance with DIN 1946/4 standard test criteria and are manufactured with LAF HVAC validation guaranteed.

laminator

H14 hepa filters

Hepa filter test report

Homogeneous air distribution

Low pressure loss

Tightness test channels

Gasket tightness test

test probes

Easy assembling

easy disassembly

decorative panel

stainless steel material

led lighting

Alperen laminar flow units consist of stainless steel air distribution box, hepa filters, transparent air distributor and operating room lighting lamp connection. The laminator provides a vertical air flow towards the operating table. Thus, particles and microorganisms present in the air flow area are immediately removed from the environment, providing a high degree of cleanliness around the operating table.

When the pressure difference in laminar flow units doubles the nominal value, hepa filters should be replaced with new ones.

What is a Laminator / Laminizer?

The laminarizer is a transparent curtain-like equipment made of special production textile material, which provides homogeneous vertical air blowing of the laminar air flow unit at a speed in accordance with the standards.

According to DIN 1964/4, the minimum amount of air to be sent to the operating room volumes is 2400 m3/h and at least 50% of this amount must be fresh air. Laminizer is made of special production textile. The laminarizer, which is fixed after being stretched on the aluminum frame, is fixed to its slot in the plenum cell. Laminarizers can be easily disassembled and reassembled for hepa filter replacement or periodic maintenance and cleaning. There is an opening of 250 x 250 mm in the middle joints of the laminators, which are made in two or four parts according to their size. This space left for the operating room lamp is closed with a gasketed collar with a 125 mm hole after assembly.

Plenum boxes are produced without curtains, with elastic PVC curtains or with plexiglass curtains, depending on demand. Hepa filters are mounted to the hepa filter housings made of stainless material in the plenum cell with special frames that provide impermeability. To replace the filters, the laminator must be disassembled. A differential pressure switch, which signals in case of contamination of the filter, is mounted on the Hepa filter boxes upon request. Laminar air flow units, hepa filters and accessories, laminarizer and parts are shipped disassembled for ease of assembly.

There are two to four hepa filter slots, depending on the size of the laminar ceiling unit, in the plenum box, which is made of stainless material. There is a stainless frame around the plenum box for the installation of the curtain.

Hepa filters are mounted to their slots in the plenum cell with special frames that provide impermeability. To replace the filters, the laminator must be disassembled.

Laminar air flow units, hepa filters and compression accessories, laminarizer and its parts are shipped disassembled for ease of assembly.

Alperen laminar flow units are designed to reduce the number of particles to less than 1 in 1 m³ of air by providing stable, vertical air flow in the protection area in surgical operations. The vertical flowing air coming out of the laminar flow units removes the pollutants in the ambient air. Thanks to its special design, it minimizes the risks of microorganism contamination with homogeneous flow. In addition, vertical flow dilutes the harmful gas concentration in the anesthesiology area in the operating room and ensures that it is removed from the environment.

H14 class special hepa filters with high flow, high permeability and 140 pa low initial pressure are used in Alperen laminar flow units.

After manufacturing, our laminar flow units are subjected to gasket sealing test in accordance with DIN 1946/4 and DIN 25414 standards.

With Alp laminar flow units, homogeneous air distribution is ensured thanks to the aesthetically pleasing, decorative panel made of stainless steel and the air distributor system consisting of a laminarizer.

Our laminar flow units are manufactured with led lighting.

Alperen laminar flow units are manufactured from stainless steel material that is resistant to the corrosive effect of disinfectants. In order to make hygienic cleaning easy, care was taken not to create too many corner details and indentations in the unit during the design. In order not to damage the filter during the installation of the HEPA filter, filter housings with leak-proof and tightness test channels are installed inside the unit.

Test aerosol sampling probes were used in the high pressure region to be used in the validation of laminar flow units.

What is Laminar Flow Cabin?

Laminar flow cabinets, or sterile cabinets, are units that provide an environment free from dust and particles with a hepa filter when working in a laboratory environment. While the air in the room is taken into the cabin, it is passed through the hepa filter. Air free of particles is obtained by filtering in the cabin. Only the air inside the laminar flow cabinets, which are also referred to as sterile cabinets, is sterile. They are not effective on the ambient air that the personnel breathe.

Laminar flow cabinets have vertical air flow.

Laminar flow cabinets should never be used to work with drug formulations, infectious material, radioactivity or any other harmful material. For these purposes, a biological safety cabinet designed to protect both the experiment and the personnel should be used. Laminar flow cabinets are also called sterile cabinets, laminar flow cabinet, laminar air cabinet, laminar air flow cabinet, laminar flow bench, safety cabinet or sterile planting cabinet.

Where Are Laminar Flow Cabinets Used?

Laminar flow cabins;

In research on non-biohazardous materials,

In drug preparation,

In media plate preparation and microorganism cultivation,

In harmless cell culture and tissue culture research,

In RNA/DNA tests,

In medical device assemblies,

They are used in sterile equipment and electronic device assembly.

You can call our company to meet all your technical and commercial demands regarding laminar air flow units and laminar flow cabinets.

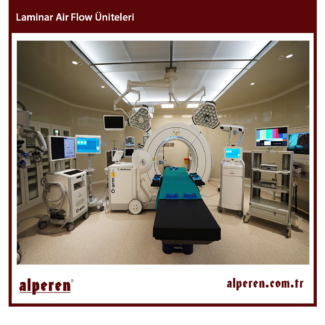

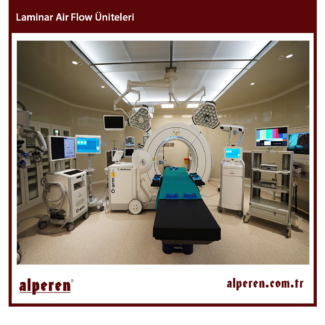

Laminar Air Flow Units Photos;

PRODUCT CATALOG

PRODUCT CATALOG