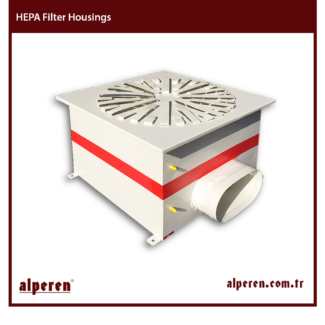

Hepa Filter Housings

Alp HEPA filter housings are the equipment manufactured to distribute the air coming from HEPA filters to a sterile space hygienically and homogeneously. They are designed to facilitate the assembly and replacement of HEPA filters.

Areas of Usage;

- They are used in laboratories,

- operating rooms,

- intensive care units,

- clean rooms,

- chemical industry,

- pharmaceutical industry,

- food industry,

- electronics industry,

- film and sound industry,

- nuclear technology industry and in all places where hygienic ventilation systems are used.

Alp HEPA filter housings manufactured in our factory in Istanbul from scoured steel plate with laser and CNC technology are seal welded. Seal slots are jointless and weldless. Air inlet directions of Alp HEPA filter housings are circular and placed on the top and sides. Impermeable dampers can be applied to the inlet of the housing upon request. Inner and outer surfaces of Alp HEPA housings are coated with RAL 7045 electrostatic paint. Valves are attached to air inlets of HEPA housings upon request. Valve dimensions are manufactured in accordance with the diameter of HEPA filter housing ducts. In Alp HEPA housings, 68, 78, 152 and 292 mm-high Alp HEPA filters are standard.

Swirl diffusers are use in Alp HEPA housings to provide an homogeneous air distribution in the space. These diffusers are made of perforated sheet and they have plastic guiding fins. Alp filter housings can be used in different ceiling applications. They are suitable for standard grid ceilings. It is easy and practical to assemble or disassemble the filter in our HEPA filter housings. The air passing through the inlet of our HEPA filter housing flows on the surface of HEPA filter. Purged from the particles by HEPA filter, the cleaned air is homogeneously distributed across the space via plastic finned swirl diffuser. All of our HEPA filter housings are tested according to DIN 1946/4 and put into use with 100% impermeability guarantee.

Properties of Alp HEPA filter housings

- Manufactured from A1 quality sheet with laser and CNC technology and hermetic.

- Testing flume for tightness and test tube in accordance with DIN 25414 and DIN 1946/4 standard for seal integrity test

- Aerosolized sampling probe for PAO filter integrity test

- Differential pressure manometer and differential pressurestat connection probe

- Electrostatic powder coating application to protect inner and outer surfaces against corrosion

- Circular, rectangular or elliptical section application for air inlets on top or at sides

- Special design without using any sealing liquid to provide sealing pursuant to DIN 1946/4 standard in the manufacture of HEPA filter housings

- Capability of mounting flat (EPDM), cast polyurethane seal or gel filters in the same housing by means of the special design of HEPA filter housings

- Special design HEPA filter housing tested for seal integrity during manufacture

- HVAC validation and guaranteed integrity test in PQ tests

Alp HEPA filter housings consist of three main parts

- Special design low body

- Easy-to-use filter pressing apparatus

- Metal swirl diffuser.

Alp HEPA filter housings bear the following parts as standard;

- Hanger handles and hanger holes

- Channel connection junction enabling air intake from top or side upon request

- Testing flume for tightness and test tube in accordance with DIN 25414 standard for seal integrity test

- Aerosolized sampling probe for PAO test and differential pressurestat connection probe

- Special design seal recess for sealed assembly of HEPA filter

- Fastened rivet nuts for easy assembly of diffuser to housing

- Special design perforated and plastic blade diffuser to provide homogeneous air distribution.

HEPA filters in various classes between H10 and H16 with various thickness can be used in Alp HEPA filter housings. The weight of our HEPA filter housings varies between 12 kg and 52 kg depending on their dimensions and construction. All of our HEPA filter housings are tested for permeability.

Differential manometer nozzles are standard in Alp HEPA filter housings to observe the operating conditions of filters. Our HEPA housings are equipped with nozzles on the filter side to apply H13 / H14 class test aerosol in accordance with EN 1882 standards. Bases of HEPA filters provide airtightness specified in DIN 1946/4. There is a test mechanism in our HEPA housings to measure airtightness. Inner and outer surfaces of our HEPA housings are not deformed when disinfected and corrosion-resistant.

Assembly of Alp HEPA filters and HEPA housings

Alp HEPA filter housings are mounted on the ceiling with tie bars via their hanger handles as standard. Can be connected to main channel with a flexible channel. Channel connection can be either on top or at the side. HEPA filter is placed in HEPA filter housing after it is fastened up. The springs inside the HEPA filter housing compress the HEPA filter laterally and enable installation by one person. Then compression parts supplied with the product are placed in the corners of the housing. HEPA filter is screwed down by gently turning the screw with hex key. There are polyethylene seals at the end of HEPA filter of the clamping elements to protect the filter case. Filters can be easily replaced by removing the diffuser.

Connection of the diffuser with HEPA filter housing is easily made with M5x10 mm countersunk bolts provided with the product. All other details related to assembly are included in the Installation Guide

Related Photos;

PRODUCT CATALOG

PRODUCT CATALOG