Energy Efficiency in Heat Recovery Units

Energy efficiency is a critical factor for environmental and economic sustainability in today’s energy-intensive world. In industrial and commercial sectors, as well as in buildings and various industrial applications, the design, manufacturing, operation, and management of heating, cooling, ventilation, and filtration systems play a significant role in the efficient use of energy. In this context, heat recovery units provide highly effective solutions for enhancing energy efficiency and reducing environmental impact.

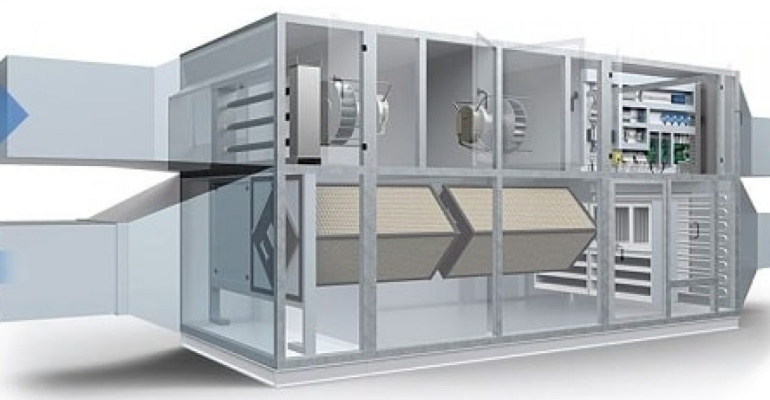

Heat recovery units are designed to minimize the loss of used energy and to reuse the captured waste heat. These units are widely employed in industrial facilities, office buildings, commercial structures, and even residential settings. Produced in various designs and capacities, when operated correctly, heat recovery units offer significant opportunities to improve system efficiency and reduce energy consumption.

Basic Principle and Operating Method of Heat Recovery Units

Heat recovery units are devices that allow waste heat generated in a system to be used in another process. Essentially, they convert the hot air or waste gases from a system into reusable energy for processes like heating or cooling. This enables desired temperature levels to be achieved without consuming additional energy.

A typical heat recovery unit transfers heat between two streams, which may consist of air, water, steam, or other fluids. One example is a system where warm exhaust air from ventilation is used to preheat fresh incoming air. Another example is the use of waste hot gases from industrial processes to heat water in cooling systems via fluid-to-gas heat exchangers.

Methods for Achieving Energy Efficiency with Heat Recovery Units

1. Reuse of Waste Heat

The primary purpose of heat recovery units is to reclaim waste heat produced by the system. Especially in industrial facilities and commercial buildings, HVAC systems consume large amounts of energy. Heat recovery units can reclaim a significant portion of this energy, reducing the need for additional energy sources and lowering overall energy consumption.

For example, hot air from an industrial furnace can be reused via a heat recovery unit to help control indoor temperature levels. This leads to reduced energy costs and more efficient heating systems.

2. Efficient Heat Transfer Systems

The effectiveness of heat recovery units is directly linked to the efficiency of heat transfer. High-efficiency heat exchangers transfer heat between environments with minimal energy loss. Modern heat exchange technologies such as plate heat exchangers, spiral heat exchangers, and tube heat exchangers enable high-efficiency recovery of waste heat.

These devices are optimized in terms of material and design to reduce heat loss and lower energy consumption. Especially in situations with large temperature differences, efficient heat exchangers perform even more effectively.

3. Smart Management Systems

For heat recovery systems to operate efficiently, intelligent management is essential. Smart control systems monitor heating and cooling demands, waste heat levels, and current energy conditions. These automated monitoring and control systems ensure that the unit operates only when needed, preventing unnecessary energy use.

Today, Building Management Systems (BMS) and Energy Management Systems (EMS) can be integrated with heat recovery units to support efficient operation. These systems monitor energy consumption in real-time and optimize energy use based on demand.

4. Efficient Filtration and Cleaning Systems

The efficiency of heat recovery units is closely related to regular maintenance and cleaning. Filters are critical components that ensure proper ventilation and airflow within the units. Dirty filters can obstruct airflow and hinder efficient operation, leading to increased energy consumption.

Regular maintenance and cleaning of systems improve airflow and allow for more efficient operation. Additionally, using advanced filters enhances air quality while also improving the unit’s energy efficiency.

5. Proper Sizing and Design of Heat Recovery Units

Selecting the appropriately sized heat recovery unit for each building is crucial. Oversized or undersized units may operate inefficiently and lead to higher energy consumption. Heat recovery units should be designed and sized according to the system’s needs. With proper planning and design, the most suitable unit can be chosen to ensure long-term energy savings.

Heat Recovery Units and a Sustainable Future

Energy efficiency and sustainability are becoming increasingly important. Heat recovery units offer excellent solutions that both reduce environmental impact and lower operational costs. By reusing waste heat, these systems contribute to the more efficient use of natural resources.

Heat recovery, particularly in industrial settings, holds great potential. Heating and cooling processes in industry are energy-intensive and environmentally impactful. Reusing waste heat through recovery units provides both economic and environmental benefits. In addition to promoting energy efficiency, these systems help reduce global warming and carbon emissions.

Heat recovery units are vital tools for improving energy efficiency and supporting environmental sustainability. With efficient design, advanced technologies, and regular maintenance, they lower operational costs and reduce environmental impact. Energy engineers, mechanical engineers, and industrial facility managers can take significant steps toward a more efficient future by maximizing the effectiveness of these systems. Heat recovery units offer an excellent response to the modern world’s energy efficiency needs.

İlker KURAN

Alperen Engineering Ltd. Co.