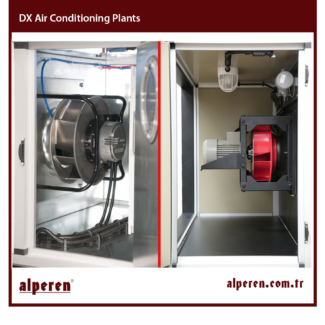

DX Air Conditioning Plants

Alp DX air-conditioning plants consist of combined module cells required based on your project.

The frame (carcass) of module cells of our Alp DX air-conditioning plants are manufactured from natural anodized aluminum profile and corner elements. Cell panels are 42 mm-thick and the outer wall is made of galvanized sheet coated with electrostatic powder paint and inner wall is made of galvanized sheet.

Alp DX air-conditioning plants are an indispensable part of central ventilation and air-conditioning applications due to their high efficiency and energy saving, 70 kg/m3 dense rock wool filled panels, modern carcass structure, statically and dynamically balanced, silent and efficient plug fans. Our electric motors are 380V-50Hz as standard. EC motor high efficiency plug fans are also used upon request.

All double wall panels are mounted on the aluminum frame with special torch tip M6 bolts. Service and inspection covers are rigid hinged and void-free as standard and airtight air conditioning unit locking system which doesn’t overhang in the cell is used. The covers are rigid and double-walled so they don’t rub the carcass frames. There are 180 mm-height chassis feet made of 2 mm-thick galvanized sheet under the cells. There are lifting lugs for craning and knife slots for carrying with forklift in the corners of chassis feet.

All grooves needed for automation such as grooves for differential pressure switch, NTC temperature sensor, freeze thermostat etc. are chamfered on Alp DX air-conditioning plants at production stage. Motor connection cables are enclosed in the junction box outside the cell. Automation equipment are collected on the panel of the device, fine-tuned and tested before delivery.

Cell joining elements are made of aluminum alloy material. Joining apparatus used to connect the cells with each other externally have a high-strength structure.

The interior lighting lamp and sight glass are placed in the aspirator, ventilator and filter cells of air-conditioning plants. These accessories enable inspection of the cells in an illuminated environment without deactivating the system.

Usage Properties of DX Batteries:

DX batteries load the heat obtained from the air driven by a compressor passing through the evaporator to cooling fluid and cool the air or heat the air by performing just the opposite of this process.

An external VRF unit is connected to a direct expansion refrigerant battery adapted to air-conditioning plant. During this process the coolant is vaporized directly in the source of heat transfer, that is in AHU.

In heat transfer by conventional cooling groups like chillers or hot water boilers, the heat is first transferred to water and later on, heat is transferred in AHU by way of pipes and pumps.

An AHU with DX battery performs on-site air-conditioning with the operation of heat pump without the need of conventional cooling groups.

Alp DX air-conditioning plants use minimum energy and operate at high efficiency. They are airtight and minimize heat bridges. Special impact absorbers are used in Alp DX air-conditioning plants to prevent vibration caused by dynamic forces.

Alp DX air-conditioning plants are designed and selected on the basis of low operating costs and high efficiency.

Energy saving fans, efficient heat recovery exchangers and serpentines, and internal plant structure which optimally balances the air flow are used in our products to support these priorities.

Efficiency and energy saving are much better with our automation systems.

Advantages of Alp DX Air-Conditioning Plants:

- Energy loss in fluid pipes is very low,

- It is an advantageous system with high COP values both in terms of operating and investment costs.

- Provides a new, easy and fast solution in establishments with a one-way investment,

- Reduces heating and cooling costs,

- Provides optimum control with variable capacity compressors and fans having inverter technology,

- It consumes only the required energy as it is controlled locally.

- Fast response to partial loads,

- Saves space needed for water cooling group and boiler,

- All automation scenarios for safe and trouble-free operation of the system are in conformity with the Heat Pump External Unit system and comes in a package with DX Air-Conditioning Plant. DX Air-Conditioning Plant and Heat Pump External Unit are synchronized.

- -Enters into the regime in a very short time, (????????)

- There is no risk of freezing for AHU water serpentine as in the conventional systems,

- Maintenance costs are very low as compared to conventional systems,

- Have low noise level,

- The static load added to the structure by steel piping, the amount of water flowing through the pump and pipe in chillers and hot water boiler systems is less in DX system,

- It doesn’t need indoor space as it is in conformity with outdoor conditions,

- Our Alp DX Air-Conditioning Plants are produced with 1800 and 25000 m³/h air volume and 14-224 kW cooling capacity.

- High efficiency heat recovery rotor or plate recuperator provides high level of energy saving.

- Alp DX Air-Conditioning Plants have a 42 mm-thick rock wool insulated and 50kg/m³ panel structure.

- All required safety and warning signs and capacity information labels are available on Alp DX Air-Conditioning Plants.

- Fans are directly coupled to motor shaft suitable for control by the frequency inverter. EC motor plug fans are also used upon request.

- Fan and motor powers are selected in consideration of pressure losses caused by dirty filters.

- Alp Air-Conditioning Plants are equipped with built-in MCC (Magnetic Control Center) and DDC (Direct Digital Control) panels in appropriate protection class.

- Apart from MCC and DDC panels, emergency safety button is standard.

- A compact switch which disconnects the device from the mains during emergency response is available.

- EEV (electronic expansion valve) and temperature sensors are installed in Alp Air-Conditioning Plants at manufacturing stage and are protected from outdoor weather conditions.

- In case of defrost in the VRF unit connected to DX Air-Conditioning Plants, the control system of air-conditioning plant automatically transits to stand-by mode without any alarm.

- DX batteries are selected in the manner to serve as cooling evaporators in summers and heating condensers in winters.

- Sight glass, siphon and accessories are standard in Alp Air-Conditioning Plants.

- Mechanical installation, cable end connections of Alp Air-Conditioning Plants and external VRF unit are done and they are commissioned by our company. Training for

- commissioning and basic maintenance are provided by our company.

- Optionally, frequency inverter is used for AC motor fan. The frequency inverters used for motor control have high EMC filtering capability.

- Plug fans calculate the pressure difference with internal inverter and control air volume.

- The air volume flowing through the DX battery is stabilized by the controller via frequency inverter.

- Optionally, the microprocessor controller in DDC panel is capable of communicating with at least one communication protocol.

- Optionally, the microprocessor controller is programmed with software suitable for the operating logic of DX systems. Critical operating scenarios with mutual alarm controls such as Hot Start, Defrost Time, Defrost Cycle etc. are included in the software of Alp DX air-conditioning plants. Thus, maximum system security measures are taken.

- Equipment such as damper motors, differential pressure sensors, temperature and humidity sensors, CO2 or CO/VOC sensors, 3-way valve bodies, proportional valve actuators, freeze protection etc. are optional and all field sensors and control equipment are mounted on Alp DX air-conditioning plants.

Related Photos;

PRODUCT CATALOG

PRODUCT CATALOG