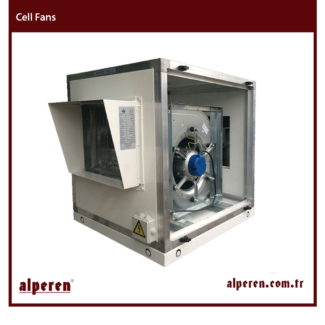

Cell Fans

Carcass of our Alp, standard cell fans are manufactured from natural anodized aluminum profile and plastic corner elements. Cell panels are optionally 25 mm or 42 mm-thick and outer wall is made of electrostatic powder coated galvanized sheet while the inner wall is made of galvanized sheet. They are an important part of central ventilation applications with their energy saving panels filled with 70kg/m3 dense rock wool,

modern carcass structure, statically and dynamically balanced, silent, efficient double inlet (suction) fans or optionally plug fans. Our electric motors are 380V-50Hz as standard.

The fan motor kit used in Alp standard cell fans and vibration are on a vibration isolating chassis and power is transmitted with belt and pulley connection. This system enables adjustment of fan speed is as desired and optimum volume and pressure adjustments can be made.

All double wall panels are mounted on the aluminum carcass with screws. Service and inspection covers are rigid hinged and void-free as standard and airtight air conditioning unit locking system

which doesn’t overhang in the cell is used. The covers are rigid and double-walled so they don’t rub the carcass frames. There are 180 mm-height chassis feet made of 2 mm-thick galvanized sheet under the cells. There are lifting lugs for craning and knife slots for carrying with forklift in the corners of chassis feet.

In order to increase the quality of fresh air supplied to the space, rough filter or compact filter can be added upon request.

Places of Usage:

Our standard type Alp cell fans are used in places such as workplaces, offices, cafeterias, markets, restaurants, meeting halls, shopping malls, hospitals, kitchens and industrial plants to supply fresh air or discharge the polluted air.

ALP ECO SERIES CELL FANS

Eco series Alp cell fans are high quality hermetic ventilation equipment to freshen or discharge requested volume of ambient air in places where heating or cooling is not required.

Places of Usage:

They are used in all places where air circulation is needed such as workplaces, offices, cafeterias, markets, restaurants, meeting halls, shopping malls, hospitals, kitchens, industrial plants, banks etc.

Structure of Eco Series Alp Cell Fans

Carcass of our economic single-cell Alp aspirators is manufactured from natural anodized aluminum profile and corner elements. Cell panels are 25 mm-thick and outer wall is coated with electrostatic

powder paint. Inner wall is manufactured from galvanized sheet. By virtue of their insulated panels, carcass structure, statically and dynamically balanced, silent and efficient double suction radial fans

they are essential for central ventilation applications. Our electric motors are 380V-50Hz as standard.

Power transmission in the fan motor kit of ALP ECO series cell aspirators is provided by belt and pulley mechanism. In this series, double suction radial fans are used and electric motor

is mounted on top of the fan. Belt pulley mechanism enables adjustment of fan speed as desired and optimum volume and pressure settings are obtained. All double wall panels are mounted on the aluminum carcass with screws. Service and inspection covers are ratchet and airtight as standard. There are 100 mm-thick feet made of galvanized sheet

under the cells. It is possible to add G3, G4, F7, F9 or carbon filter to increase the quality of fresh air to be supplied to the space upon request.

ALP EX-PROOF SERIES CELL FANS

Alp Ex-Proof Series cell fans contain double suction radial fans made of copper and suction funnel has the feature of preventing sparks between the rotor and the body in case of metal impact.

Our electric motors are ex-proof and 380V-50Hz.

Places of Usage:

Alp Ex-Proof series cell fans are used in prominent industries such as petrochemical, pharmaceutical, paint, food, crude oil and natural gas transmission. In consideration of explosive gases in these industries, cell fans in the most accurate protection class are manufactured by making no concessions to security.

Ex-proof motors and fans maintain their operating temperature while the ambient temperature increases. Our ex-proof motorized and fanned cells, which meet the highest safety standards are designed to be safely operated in environments where explosive substances exist.

ALP SINGLE CELL KITCHEN ASPIRATORS

ALP-M kitchen type cell aspirators are designed for the purpose of exhausting the hot, oil bath and humid air emitted during cooking in industrial kitchens and cooking areas.

The carcass of our kitchen type cell aspirators are manufactured from natural anodized aluminum profile and plastic corner elements. Cell panels are optionally 25 mm or 42 mm-thick

and the outer wall is manufactured from electrostatic powder coated galvanized sheet. They are an important part of central ventilation applications with their energy saving panels filled with 70kg/m3 dense rock wool,

modern carcass structure, statically and dynamically balanced, silent, efficient plug fans.

Our electric motors are 380V-50Hz as standard.

In our ALP-M series kitchen type cell aspirators, electric motor of the fan is insulated so that it is not exposed to air flow.

By virtue of the oil trap filter in their inlet, kitchen aspirators retain the oil and carbon black particles in the intake air and clean the air exhausted to atmosphere. Oil trap filter, drain flute and the drain pan

designed to drain the condensed oil and moisture, and the water and chemicals used during chemical cleaning and

and drain outlet are standard components. It is suitable for operation with frequency inverter. All double wall panels are mounted on the aluminum carcass with screws. Service and inspection covers

are rigid hinged and void-free as standard and airtight air conditioning unit locking system which doesn’t overhang in the cell is used. The covers are rigid and

double-walled so they don’t rub the carcass frames. There are chassis feet made of 2 mm-thick galvanized sheet and vibration isolation plastic mountings under the cells. There are knife slots on the feet of chassis

to carry them with a forklift.

Related Photos;

PRODUCT CATALOG

PRODUCT CATALOG