What is a Fan Filter Unit?

FFU – Fan Filter Unit is a kind of fan air filtering equipment. They are used to provide purified air in clean rooms by removing harmful airborne particles from the circulation air. The unit is mounted to be placed in the ceiling void of the system or in a suspended ceiling grid system. A proportionally large number of filter units with fan can be used for large-volume clean rooms. Each unit has a filter group, fan and air distribution equipment. They can be controlled manually, automatically or with a central system.

from the circulation air. The unit is mounted to be placed in the ceiling void of the system or in a suspended ceiling grid system. A proportionally large number of filter units with fan can be used for large-volume clean rooms. Each unit has a filter group, fan and air distribution equipment. They can be controlled manually, automatically or with a central system.

Alp fan filter units are self-fan package type air filtration equipment designed for clean room applications where high air quality is required. They are manufactured to create suitable areas in the desired room class without the need for HVAC system installation.

Where is the Fan Filter Unit used?

Alp FFU fan filter units, aviation and space industry, pharmaceutical industry, manufacture of biotechnology products, medical sector, laboratories, water filling facilities, food industry, electronics industry, chemical industry, optical industry, cosmetics industry, genetic engineering, manufacturing of nano technology products, They are designed to keep the quality of application, production, assembly and analysis high by controlling the number of particles in the environment in sectors where air sterilization is important such as the textile industry and automotive industry, and to achieve efficient and standard results.

In order to achieve the desired air quality, Alperen fan filter units can be used in clean room ceiling applications as well as alone in laminar flow cabins.

How Does a Fan Filter Unit Work?

Alp fan filter units return the air that it absorbs from the environment through a pre-filter and hepa filter to the environment in a way that is free of particles. Thus, the required sterile environment is provided for the applications and manufacturing by bringing the ambient air to the desired clean room class with its high cycle number.

Alp fan filter units are manufactured using hepa13, hepa14, hepa15, hepa16 or hepa17 class filters with efficiency varying between 99.97 and 99.999997 according to EN1822 standard. Leakage test certificates are delivered with the product.

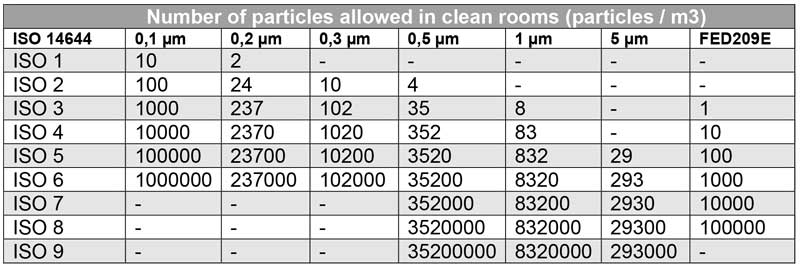

Clean room classes have been established in international standards for the number of particles kept under control.

According to FED 209E, the total number of particles 0.5 micron and larger per square foot in a room determines the class of the room. For example, it is defined as Class 1000 for a cleanroom with a total number of particles 0.5 micron per square foot and larger, between 100 and 1000.

The TS 11605 EN ISO 14644-1 standard is divided into ISO classification limits used to define the cleanliness of the air in clean rooms and environments controlled together. It describes the standard trial method as well as the determination of the concentration of airborne particles.

In the TS 11605 EN ISO 14644-1 standard, a size range designed for these particles is given to determine the particle concentration limits for classification purposes. The TS 11605 EN ISO 14644-1 standard also provides standard protocols for the determination and design of cleaning levels based on airborne concentration of particles larger or smaller than the designed particle size range in the classification.

What are the Features of the Fan Filter Unit?

Alp fan filter units, which can be used in all applications with clean room class class 1 to clas 100000, are specially produced for your project in different sizes and capacities according to your needs. Our FFU units are self-fanned and have pre-filter and hepa filter that work in accordance with recurkile systems. With these features, Alperen fan filter units offer flexible and economical solutions to remove particles in the circulation air of clean rooms with turbulence or unidirectional ventilation.

Alp fan filter units provide hygienic air by filtering the particles in the air with their integrated pre-filter, hepa filter, fan and control system.

Due to the constructive nature of Alp fan filter units, you will not have any problems during the tests performed at the validation stages.

Thanks to its ergonomic design, the Alperen fan filter units, which are extremely easy to install, have a very low noise level and energy consumption. There are test probes on the unit for DOP sealing test. Our products are manufactured from Ereğli A1 quality DKP sheet furnace painted or from Cr-Ni 304 or Cr-Ni 316 quality stainless steel sheet.

Upon your request, accessories such as manometer and speed control device can be mounted to the Alp fan filter units, which operate with 220 volts of electricity.

- High quality filter elements,

- High energy efficiency,

- Homogeneous air distribution,

- Quick and easy installation,

- Easy to change filters,

- Leak-proof guarantee,

- Independent use,

- Low operating cost,

- Low energy consumption,

- Quiet working,

- Connecting to the building management system,

- Optional accessories.

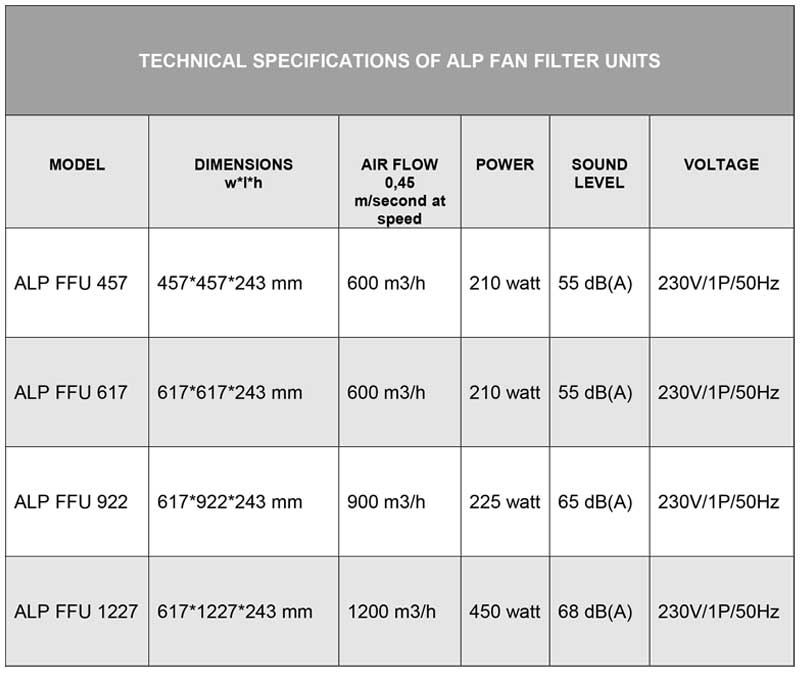

Fan Filter Unit Dimensions

Alp fan filter units are also produced in sizes and capacities specific to your project. You can view our standard sizes from the table below.

Alperen fan filter units are offered to you with their advantages in investment cost, power consumption and service issues, as well as a design that provides ease of installation. Thanks to the fans with adjustable speeds, as the filters get dirty, the fan speed is increased and the desired flow rate and clean room standard is achieved. High efficiency filters are very easy to change.

You can call our company for your questions and requests about Alp fan filter units.

Alp FFU – Fan Filter Units Photos;