Active Carbon Filters

APF • Activated Carbon Panel Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Impregnated with activated carbon powder. Provides odor retention with 30 to 35% efficiency

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well as alcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced from active carbon powder impregnated synthetic filter material placed inmoisture-resistant cardboard frame and supported with wire mesh folded in zig-zag form.

ADF • Activated Carbon Filling Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Is easy to install thanks to its compact structure. Provides high odor retention with 80% – 90% efficiency.

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well asalcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced by filling the plastic panels that make up the filter frame with activated carbon granules.

AKF • Activated Carbon Compact Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Provides high odor retention with 80% – 90% efficiency and ensures F7 class filtration efficiency thanks to the two-layer filter material and activated granular carbon particles thereof.

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well asalcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced by activated carbon granules placed between two synthetic filter layers.

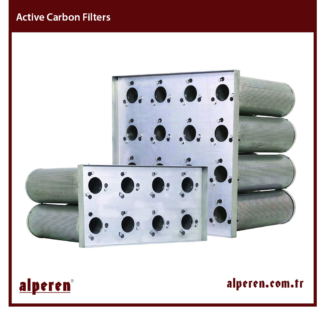

KKF • Activated Carbon Cartridge Filter

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Provides high odor retention with 80% – 90% efficiency. Can be filled easily with clips placed on the covers

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well as alcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced of galvanized metal in cylindrical shape in models with 4, 6, 8 and 16 cartridges with openable covers which facilitates the replacement of active carbon granules in it layers.

AGK • ACTIVATED GRANULAR CARBON

Aim of Use : Used as odor arresting filter material.

Features : Provides high odor retention with 80% – 90% efficiency.

Area of Use : Used in carbon filters and non-standard filter applications.

Production Method: Produced of mini carbon particles with 4 mm diameter and in various sizes.

Related Photos;

PRODUCT CATALOG

PRODUCT CATALOG