Hepa and Ulpa Filters

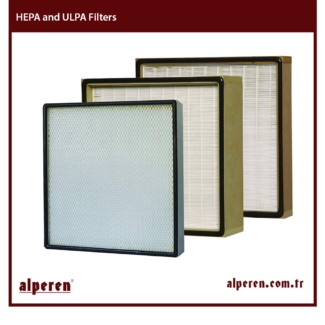

PHF • Panel Hepa Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter.

Features : Offered with test results conducted according to EN 1822 with the productto the user.

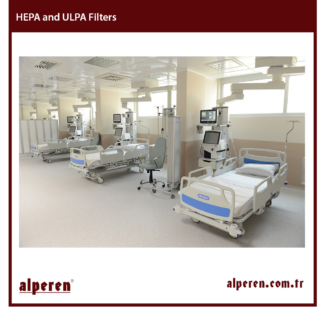

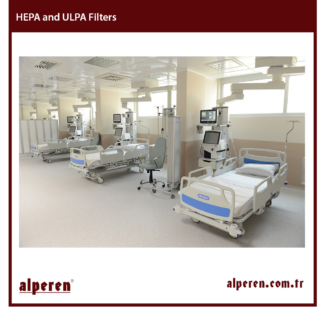

Area of Use : Used in places requiring precise filtration such as hospitals, pharmaceutical factories, clean rooms, industrial facilities and etc.

Production Method: Produced from fiber glass paper after being folded through mini pleat technology and by placingin MDF or aluminum frame by closing the frame edges with polyurethane based glue

Efficiency Class : H10 (EU10) – H13 (EU13) – H14 (EU14) – U15 (EU15)

PHF / A : with Aluminum Frame PHF / M: with MDF Frame

HVF • High Flow Hepa Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter.

Features : Offered with test results conducted according to EN 1822 with the product to the user.

Area of Use : Used in high flow in environments that require hepa level filtration.Production Method: Produced from micro-glass fiber paper lined in V shape after being folded through mini pleat technology and by placing in galvanized frame by closing the frame edges with polyurethane based glue.

Efficiency Class : H10 (EU10) – H13 (EU13) – H14 (EU14) – U15 (EU15)

HDF • Hepa Terminal Hood Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter with hood.

Features : Allows complete sealing and easy usage. Offered with test results conductedaccording to EN 1822 with the product to the user.

Area of Use : Used in pharmaceutical, electronics, food and chemical industries other industries that require very high degree of fresh air. Production Method: Produced from hepa filter placed in sealed frame with hood that can be easily mounted between the T-shaped ceiling profiles. Efficiency Class : H13 (EU13) – H14 (EU14) – U15 (EU15)

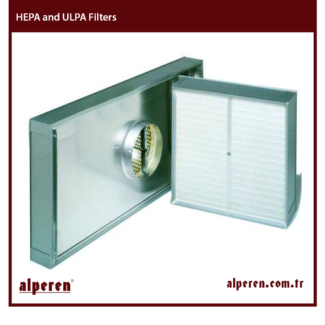

HEPABOX • Hepa Boxes

Aim of Use : Denotes the hygienic ventilation equipment used for the installation of hepa filters.

Features : Allows complete sealing and easy usage. Air intake is from the sides or from the top. Tested in accordance with DIN 1946/4 and offered to usage with 100% impermeability guarantee.

Area of Use : All projects where hepa filter applications to be utilized Production Method: Produced from stainless steel or powder coated steel sheet.

Laminar Flow Units

Alp-filters-table2. jpg Table

Related Photos;

PRODUCT CATALOG

PRODUCT CATALOG